Control systems

For me, quality controls were the main purpose of camera systems. Among other things, checked the presence, location, position, color, 1D and 2D codes, texts and spacing in various industries for all possible purposes.

- Checking packaging and labeling in the oil industry

- Control of location, shape, weight and defects in the food industry

- Inspection of batch, label and object for plastic containers

- Analysis of colors for stationery

- Monitoring the presence of all components in packaging

- Rejection of defective products and stop as well as notification in the event of an unsuccessful ejection

Security controls by camera systems are extremely attractive in order to save installation space and barriers and to work more cooperatively with machines and robots. Cameras monitor the movement space of a robot and allow its movement in the event that it is as it should be. As soon as an object, human or whatever, reaches the movement area, the release is extinguished and the robot stops. So much more can be done than just securing work areas.

Orientation

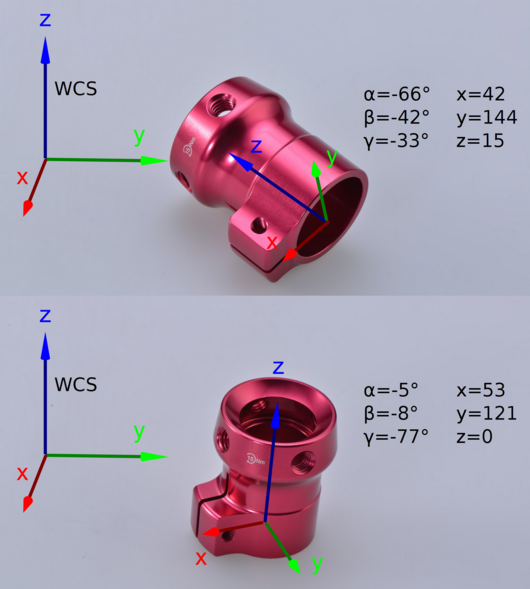

Position and position detection of objects for robots, with grippers or suction cups, for example for Pic & Place applications, are diverse.

- I programmed the handle in the box using 3D models that were used to identify the objects and their position in order to enable a robot to get the object out of the box.

- Using MV-Tec's Halcon, I programmed a position detection for picking up from the assembly line and putting it back on the assembly line. I also developed the associated HMI completely myself; the system is now used for weighing and portioning in the food industry and is part of an assembly line that is over 70 meters long.

Of course, various manufacturers are also suitable for position detection. I will be happy to help you find something that suits you.

Monitoring and logging

The logging of errors and the resulting easier troubleshooting and optimization of the systems is their sole function with some camera systems. The comparison between several production systems can be used to optimize processes or to identify wear parts that are soon overdue at an early stage.

Domain integrations, which are taken into account by a few manufacturers, are also increasingly in demand. In the case of camera systems, in which one has to be present anyway in most cases, the benefit of domain affiliation only becomes apparent when it is adequately explained when and how money can be saved with it. A central user administration saves a lot of time and ensures security, if you know who has been on the system, you know who to ask when something has changed. In addition, regular password changes and other standards are centrally regulated.

Manufacturer

Different manufacturers of camera systems, cameras and lenses or complete solutions sometimes specialize in special cases. That is why it is advisable to employ an independent developer who looks for the right one from various manufacturers.

Basler, Stemmer Imaging, Cognex, Allied Vision, Opto Engineering, Omron and Keyence are just a few of the manufacturers I have worked with. I remember exactly which ones are for quality, which for customer service, which for cheap and which are ideal for standard solutions or special cases and I am always on the lookout for new things.